Pipe Relining vs Replacement: Best Options for Drain and Sewer Pipes and How to Choose the Right Solution

Pipe relining (a trenchless repair that inserts a new bonded liner inside an existing pipe) and pipe replacement (traditional excavation to remove and install new pipe) are two distinct strategies for restoring drain and sewer infrastructure. This article will help you choose between relining and replacement by explaining how each method works, which pipe materials and damage types favor one approach over the other, and how cost, lifespan, environmental impact, and permitting influence the final decision. Many property owners face the dilemma of balancing upfront cost and property disruption against long-term reliability, and this guide maps practical decision criteria and inspection signals to recommended actions. You will find clear process descriptions for Cured-in-Place Pipe (CIPP), epoxy and pull-in-place linings, step-by-step excavation workflows, material-specific compatibility notes, itemized comparison tables, and decision matrices that let you self-assess your likely solution before calling a professional. Read on to understand trenchless sewer repair methods, how to estimate CIPP pipe repair cost versus sewer line replacement cost, and when to reline versus replace sewer pipes based on damage severity and site constraints.

What Is Pipe Relining and How Does Trenchless Repair Work?

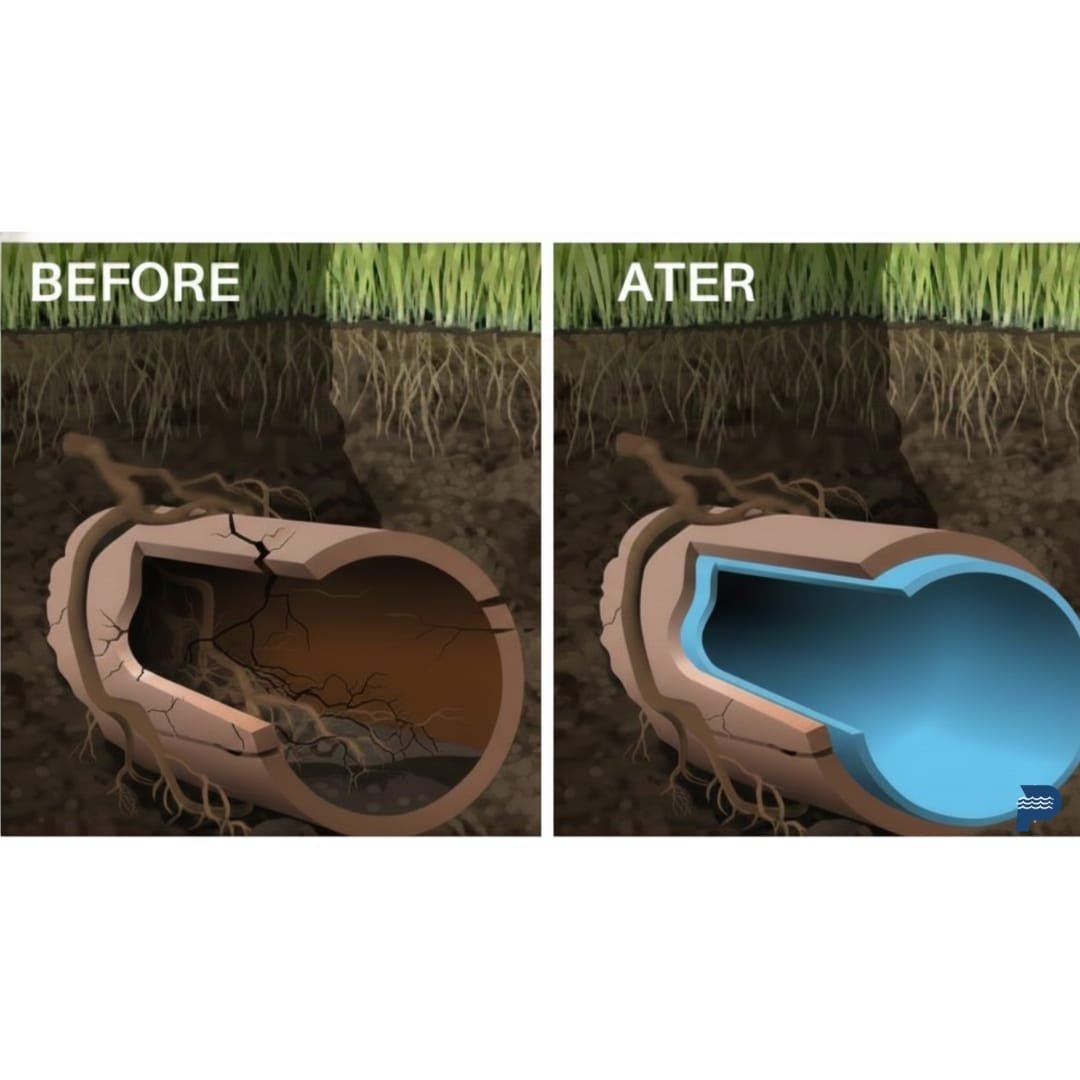

Pipe relining is a trenchless technique that restores a damaged pipe by inserting a flexible liner impregnated with resin, curing it in place to form a continuous new pipe inside the old one. The mechanism relies on a cleaned host pipe, a resin-saturated liner or spray, and a controlled curing process that bonds the new material to the existing pipe wall, which results in restored structural integrity and improved flow characteristics. The primary benefit is minimal surface excavation, which reduces restoration costs and shortens project timelines compared with full replacement. Relining is especially useful for long runs beneath landscaping, driveways, or foundations where excavation would be costly or damaging. The next section describes the most common relining technologies, their installation steps, and where each method is most appropriate.

What Are the Common Pipe Relining Methods Like CIPP and Epoxy Lining?

This subsection defines common hyponyms of trenchless repair and explains basic installation mechanics for each method so readers can match method to material and damage type. Cured-in-Place Pipe (CIPP) lining uses a fabric or felt tube saturated with thermosetting resin that is inverted or pulled into the host pipe and cured using steam, hot water, or UV light to create a seamless new pipe. Epoxy spray or coating applies a polymer resin directly to the internal surface, bonding to the substrate and sealing cracks and leaks without inserting a thick liner. Pull-in-place and sliplining involve inserting a prefabricated pipe inside the existing conduit and sometimes performing minor joint repair; these are simpler but reduce internal diameter. Each method has trade-offs: CIPP provides a strong structural liner, epoxy is excellent for sealing and small defects, and sliplining is straightforward but can compromise flow capacity. Understanding these differences clarifies which trenchless technology aligns with specific pipe materials and damage patterns.

How Does Pipe Relining Benefit Drain and Sewer Pipe Repairs?

Pipe relining benefits drain and sewer repairs by reducing surface disruption, shortening downtime, and often lowering total project cost when restoration is factored in. Because relining avoids continuous trenches, it limits the need for landscaping, paving, and structural restoration, which are common hidden costs in full replacement projects. Relined systems typically come with manufacturer or installer warranties and expected service lives comparable to many new pipes when properly specified and installed. Limitations include potential diameter reduction that can affect flow capacity and difficulty re-establishing lateral connections to branch lines without specialized reinstatement work. With these advantages and trade-offs in mind, the following section explains traditional replacement workflows and material choices where relining may not be feasible.

What Is Pipe Replacement and How Does Traditional Excavation Work?

Traditional pipe replacement removes the failing conduit and installs new pipe through open excavation, allowing full access to correct alignment, grade, and diameter deficiencies. The workflow begins with locating and marking underground utilities, opening trenches or pits, removing the old pipe, installing new material to current standards, backfilling, compaction, and restoring the surface to pre-work condition. This approach is preferred when pipes have collapsed, are extensively corroded, or when a larger diameter or re-routing is required; replacement enables comprehensive system upgrades that relining cannot accomplish. Permit requirements, municipal inspection, and extensive restoration tasks often add to project timelines and costs, so these regulatory and restoration factors must be factored into the decision. The next subsection provides a material-by-material breakdown to help map replacement necessity to specific pipe types.

Which Pipe Materials Are Used in Replacement: PVC, HDPE, Copper, and Cast Iron?

Understanding replacement materials clarifies durability expectations and compatibility with relining options because some materials age or corrode differently and affect relining adhesion. PVC and HDPE are common modern choices due to corrosion resistance, low cost, and long service life; both pair well with many lining systems and are often the go-to for new replacement. Cast iron is durable but prone to corrosion and weight-related installation constraints; older cast iron runs are frequently candidates for relining if structurally sound, but advanced corrosion may still require replacement. Copper and other metal pipes are less common for sewer mains but may be used in specialty applications; metallic materials can complicate epoxy adhesion and sometimes necessitate full replacement. These material attributes lead into an explicit pros and cons list for full replacement to weigh the trade-offs.

- Intro paragraph explaining list context and purpose (above) sets up pros/cons below.

- The list outlines clear pros and cons of replacement.

- Pros: Permanent Renewal: Replacement restores original pipe diameter and alignment, addressing structural failures and allowing full system upgrades.

- Pros: Material Selection: You can select modern, corrosion-resistant materials suited to the installation environment.

- Cons: High Disruption: Excavation causes major landscaping and pavement disturbance and higher restoration costs.

- Cons: Longer Timelines: Permits, inspections, and extensive restoration extend project duration compared with trenchless options.

These pros and cons show that replacement is decisive for severe structural failures but carries higher non-material costs, which informs the next section’s cost and longevity comparison.

How Do Pipe Relining and Replacement Compare in Cost and Longevity?

A direct comparison shows that relining typically lowers total project costs when restoration and downtime are included, while replacement often yields the longest lifecycle and greatest flexibility for upgrades. Relining per-linear-foot figures usually cover cleaning, camera inspection, liner and resin, curing, and basic reinstatement of a few lateral connections; replacement per-foot numbers often reflect only pipe and basic install but can escalate with deep excavation, site restoration, and permits. Lifespan expectations vary: well-executed CIPP and epoxy systems commonly provide decades of service, while new PVC/HDPE replacements offer long-term durability subject to correct bedding and installation. The following table gives a scannable cost and longevity comparison to help homeowners and facility managers evaluate options quickly.

| Approach | Upfront cost per ft (range) | Typical total project cost | Lifespan (typical) | Disruption level |

|---|---|---|---|---|

| Relining (CIPP/epoxy) | $50–$200 | $2,000–$25,000 (depends on access) | 25–50+ years | Low (access pits only) |

| Replacement (excavation) | $80–$300+ | $5,000–$40,000+ (restoration heavy) | 40–100 years (material-dependent) | High (trenches, restoration) |

| Sliplining / Pipe bursting | $70–$220 | $3,000–$30,000 | 30–75 years | Medium (some excavation) |

This EAV-style snapshot highlights that relining often wins on total project cost and disruption, while replacement can offer longer nominal service life depending on material selection and installation quality. The next subsection drills into typical per-foot cost drivers and what those numbers include or exclude.

What Are the Typical Costs per Linear Foot for Relining vs Replacement?

Costs per linear foot vary by access difficulty, lateral reinstatements, material prices, and required restoration; the ranges above indicate market-level variability rather than guarantees. Relining costs per foot commonly include initial camera inspection, hydro-jet cleaning, the liner or resin system, curing, and completion testing; hidden costs can include difficult reinstatement of branch connections or extra access pits. Replacement per-foot material cost may appear lower for pipe alone but balloon when excavation depth, shoring, pavement replacement, and landscaping restoration are added. Example anonymized scenarios help illustrate these differences: relining a 50-foot yard run under a paved driveway often avoids repaving costs that would add several thousand dollars to an excavation estimate. Understanding those restoration multipliers is essential to an accurate ROI comparison between trenchless repair methods and full replacement.

How Long Do Relined Pipes Last Compared to Replaced Pipes?

Relined pipes using quality CIPP systems are commonly warranted and expected to last 25–50 years, with some systems projecting longer depending on resin chemistry and installation standards. Newly replaced pipes—PVC and HDPE in particular—can have expected service lives of 50–100 years when installed with proper bedding, corrosion protection, and consideration for ground movement. Longevity is influenced by ground conditions, load, chemical exposure, and installation workmanship; inspection and maintenance (periodic camera checks and clearing) extend service life for both relined and replaced systems. Regular monitoring and targeted maintenance are therefore key to maximizing the lifespan of whichever solution is chosen.

When Should You Choose to Reline or Replace Sewer and Drain Pipes?

Short answer: choose relining for intact pipes with cracks, minor joint leaks, or root intrusion; choose replacement for collapsed runs, severe corrosion, extensive bellies, or when diameter increases or rerouting are required. This section provides a decision matrix that maps common inspection findings to recommended actions, helping non-technical readers understand threshold signals for replacement. Look for camera inspection terms like “partial collapse,” “multiple offset joints,” or “complete section loss” as indicators that replacement is likely unavoidable. After the decision guidance, readers should consult a licensed plumber or trenchless specialist for on-site inspection to confirm recommendations and obtain precise quotes.

| Damage type | Severity indicators | Recommended action | Notes |

|---|---|---|---|

| Hairline cracks | Hairline fractures, no deformation | Reline | Minimal disruption; install liner or epoxy |

| Root intrusion | Roots penetrating joints, localized | Reline + root cutting | Consider root barrier with liner |

| Corrosion | Thinning metal, multiple perforations | Replace | Cast iron with advanced corrosion often needs replacement |

| Collapse | Camera shows flattened or collapsed pipe | Replace | Structural failure mandates excavation and replacement |

What Types of Pipe Damage Are Best Suited for Relining?

Relining is most effective for hairline longitudinal cracks, minor circumferential fractures, joint leaks, and root intrusion that have not produced full structural collapse. When the host pipe retains its shape and alignment, liners bond to the interior surface to restore hydraulic capacity and strength without removing the existing conduit. Relining can also seal infiltration points and create a smooth, corrosion-resistant interior that reduces future root ingress. Limitations include situations with large deformations, severe offsets, or missing sections; in those cases, relining cannot restore proper grade or flow and replacement should be considered. The next subsection explains inspection findings that push the decision toward full replacement.

When Is Pipe Replacement Necessary Due to Severe Damage or Corrosion?

Replacement becomes necessary when camera inspections reveal structural collapse, bellied sections that trap solids, multiple failed joints, or pervasive corrosion that compromises load-bearing capacity. Indicators such as continuous longitudinal collapse, flattened ovalization, or camera footage showing sections of pipe missing or entirely crushed flag clear thresholds for excavation. Replacement is also appropriate when diameter enlargement or rerouting is required to meet updated capacity needs or when municipal codes mandate full replacement under certain failure conditions. For these scenarios, replacement eliminates repeated failures and allows specification of modern materials and gradients to prevent recurrence.

What Factors Should Influence Your Choice Between Relining and Replacement?

Several weighted factors should guide the decision: budget (short-term and life-cycle), property disruption tolerance, environmental impact, future maintenance preferences, and pipe material compatibility. Budget-sensitive projects often favor relining because the all-in cost—including restoration—is frequently lower than replacement, while long-term capital projects or properties undergoing major renovations may opt for replacement to future-proof systems. Property disruption is critical: high-value landscaping, paved driveways, or urban street cuts usually favor trenchless approaches to avoid expensive restoration. Environmental considerations such as spoil disposal and emissions from heavy equipment also tilt decisions; the next subsection compares budget, disruption, and environmental impacts more specifically.

How Do Budget, Property Disruption, and Environmental Impact Affect Your Decision?

Budget constraints typically prioritize methods that minimize restoration costs; relining reduces landscaping and paving replacement expenses and often shortens labor hours, lowering total project price. High-impact properties—those with ornamental gardens, stamped concrete, or mature trees—benefit from trenchless repair to preserve surface assets and avoid protracted replanting costs. Environmentally, trenchless methods generate less excavated spoil, produce fewer heavy-equipment emissions onsite, and reduce the need for landfill disposal of contaminated soils, making them preferable where sustainability is a factor. These considerations should be balanced with long-term goals: if the aim is a permanent system upgrade and complete line renewal, replacement may still be the best investment despite higher immediate impact.

What Role Does Pipe Material and Damage Extent Play in Choosing Repair Methods?

The interaction between pipe material and damage extent directly affects relining feasibility because some substrates bond better to resins and tolerate liner installation stresses. For example, PVC and HDPE host pipes typically present predictable surfaces for liner adhesion, while heavily corroded cast iron or friable clay may require careful cleaning or replacement if the substrate cannot support bonding. Localized defects on otherwise sound materials are prime candidates for relining, whereas diffuse, system-wide deterioration or repeated failures suggest replacement is the sounder long-term choice. Installation teams evaluate material compatibility during pre-job inspections and will recommend the method that optimizes longevity given substrate condition.

What Are the Environmental and Property Impact Differences Between Relining and Replacement?

Relining significantly reduces surface disturbance and the environmental footprint of sewer and drain repairs compared with full excavation, leading to lower restoration emissions and reduced spoil generation. The trenchless footprint is typically limited to access pits or manholes, which minimizes habitat disruption and shortens on-site emission-intensive equipment usage. However, relining does require handling of resins and curing processes that have their own environmental considerations, so selecting low-VOC resin systems and managing waste responsibly remains important. The next subsections discuss how trenchless relining minimizes disruption and outline common restoration and regulatory considerations for replacement projects.

How Does Trenchless Relining Minimize Disruption and Environmental Damage?

Trenchless relining limits excavation to small access pits, which dramatically reduces landscape disturbance, root system damage, and the need for extensive paving replacement. Shorter project durations mean less heavy machinery onsite, reducing diesel emissions and noise impacts in residential neighborhoods. Trenchless approaches also decrease the volume of soil and construction debris that requires disposal, lowering landfill burden and transportation emissions. While trenchless methods are not impact-free, their smaller physical and carbon footprint makes them an environmentally preferable option when technically feasible. This comparison naturally leads to an overview of the permits and restoration obligations that arise when replacement is required.

What Are the Restoration and Regulatory Considerations for Pipe Replacement?

Replacement projects typically trigger municipal permit requirements, mandatory inspections, and restoration standards that can include repaving, tree replacement, and landscape reinstatement bonds or warranties. Local codes often require documentation of depth, bedding, compaction tests, and final surface restoration approvals before closure, which adds administrative time and potential costs. Typical restoration tasks include soil compaction, topsoil replacement, reseeding or sod installation, and pavement resurfacing that may take weeks to months to reach final condition. Property owners should verify local permitting rules early, budget for restoration and inspection fees, and plan for schedule contingencies tied to municipal review and weather conditions.

- Permitting and approvals: Submit excavation and restoration plans to local authorities and schedule required inspections.

- Compaction and testing: Perform and document soil compaction and bedding to meet engineering standards.

- Surface restoration: Repair pavement, concrete, landscaping, and irrigation systems affected by trenching.

Carefully accounting for these regulatory and restoration elements prevents surprise costs and ensures replacement projects satisfy municipal obligations and return the property to acceptable condition.

Pipe Relining vs Replacement: Best Options for Drain and Sewer Pipes and How to Choose the Right Solution

This final line concludes the article content under the original heading structure and emphasizes that the guidance provided—process descriptions, material compatibility notes, cost/lifespan comparisons, environmental impacts, and decision matrices—should be used to inform a site-specific inspection and quote. For definitive next steps, consult a licensed plumber or trenchless specialist for an on-site sewer camera inspection and a written estimate tailored to your material type, damage extent, and restoration requirements.