Trenchless Pipe Repair Service Areas in Arizona

Trenchless Pipe Repair in Arizona — No‑Dig Solutions and Where We Work

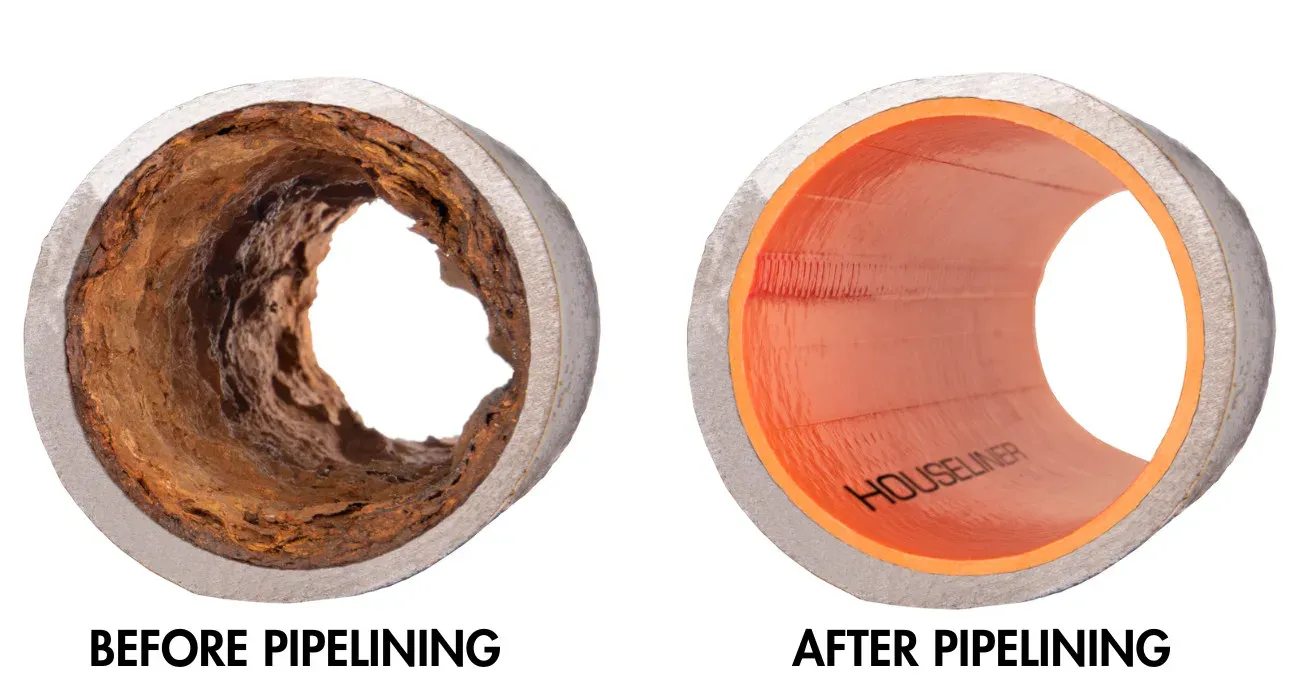

Trenchless pipe repair fixes underground water and drain lines without open trenches by rebuilding the pipe from the inside using lining systems or epoxy coatings. This guide walks you through cured‑in‑place pipe (CIPP), epoxy restorations such as ePIPE, and the prep work—like hydro jetting—that makes those methods reliable. We also explain why no‑dig approaches are often the best choice in Arizona, where caliche, shallow bedrock, mature landscaping, and aging cast‑iron systems make traditional excavation expensive and disruptive. Below you’ll find how the main trenchless methods work, where services are commonly available across the state, what to expect for cost and timing, and how to vet contractors. We’ve also included useful search phrases—trenchless services AZ, pipe relining Phoenix AZ, ePIPE restoration Arizona—to help you find local options and compare rehab versus replacement.

What is Trenchless Pipe Repair and Why is It Important in Arizona?

Trenchless pipe repair refers to techniques that rehabilitate buried pipes through access points rather than by digging continuous trenches. Typical steps include a camera inspection, interior cleaning, inserting a resin‑saturated liner or applying an epoxy coating, then curing the material so it forms a new pipe inside the old one. That approach minimizes surface damage and cuts restoration costs—especially helpful in Arizona, where caliche, bedrock, and mature landscaping make excavation costly and time‑consuming. For homeowners and property managers, trenchless methods protect yards, driveways, and hardscapes while delivering durable repairs suited to local conditions.

At Pipeliners USA we rely on CIPP and epoxy water‑line restoration as our primary no‑dig choices across Arizona. We always start with a camera inspection to match the repair method to the pipe’s condition; warranty and turnaround details appear later in this guide. With that context, the next section explains CIPP lining and material choices so you can compare options with confidence.

How CIPP Lining Restores Damaged Pipes

Cured‑in‑place pipe (CIPP) lining repairs a damaged run by inserting a flexible carrier saturated with resin into the existing pipe, then curing it so the liner becomes a continuous, joint‑free inner pipe. Work begins with a camera inspection to locate defects, followed by cleaning—typically hydro jetting—to remove roots, scale, and debris that would prevent proper adhesion. The liner is inverted or pulled into position and cured with steam, hot water, or UV light depending on the resin system. Carriers are commonly felt or fiberglass impregnated with epoxy, polyester, or vinyl ester resins that bond to the host pipe, restoring structural strength and smooth flow. A post‑cure camera check confirms the lining sealed correctly. Technicians choose materials and curing methods based on pipe diameter, damage, and site constraints—important choices in Arizona’s varied soils.

If you want deeper technical background, industry research and guidelines cover CIPP and other trenchless methods in more detail.

Trenchless Technology Guidelines: CIPP Pipe Rehabilitation

These guidelines review major trenchless rehabilitation methods—chiefly cured‑in‑place pipe (CIPP) and fold‑and‑formed pipe (FFP)—and cover small‑diameter installations using mini‑horizontal directional drilling as well as larger installations with microtunneling. Recommendations are based on extensive laboratory and field studies.

… Advancement Research (CPAR) Program. Guidelines for Trenchless Technology: Cured‑in‑Place Pipe (CIPP), Fold‑and‑Formed Pipe (FFP), Mini‑Horizontal …, S Khan, 1995

Knowing which curing method and resin are used helps you anticipate differences in project time and long‑term performance between UV‑cured systems and steam‑cured resins—details that matter for budgeting and expectations.

Why No‑Dig Repairs Work Well in Arizona’s Environment

No‑dig repairs offer benefits that are especially practical in Arizona: far less disruption to landscaping, faster completion, and durable results for rehabilitated pipes. Avoiding trenches preserves desert plantings, mature trees, and hardscapes that are costly to replace. Shorter job times also reduce crews’ heat exposure and cut downtime for homes and businesses. Modern liners and epoxy systems can last for decades and address common local issues like cast‑iron scaling and corrosion. In many cases a lined pipe’s smoother interior also improves flow and reduces repeat backups, lowering maintenance over time.

Those advantages explain where trenchless methods are most useful across the state and how local conditions shape service delivery.

Which Arizona Cities Do We Serve for Trenchless Pipe Repair?

Pipeliners USA provides trenchless sewer and water‑line restoration across multiple Arizona markets, focusing on metro areas and suburbs where underground infrastructure is aging and no‑dig repairs deliver the most value. Our coverage typically includes the Phoenix metro and nearby suburbs, Tucson and southern Arizona, and other growing communities where homeowners and commercial properties face buried pipe issues. Knowing these service areas helps property owners estimate local availability and plan inspections and scheduling.

Local variables—permits, urban density, and ground conditions—influence how we mobilize and which equipment we bring. The section below outlines city‑level constraints and how they shape method selection in places like Phoenix, Mesa, and Scottsdale.

Local Challenges in Phoenix, Mesa, and Scottsdale

Phoenix, Mesa, and Scottsdale share some challenges but also have unique factors that affect trenchless decisions. Deep caliche layers and compacted soils make open excavation expensive, increasing the appeal of no‑dig options. Dense, infill neighborhoods can limit access for large equipment, so compact trenchless setups and shorter mobilizations are often chosen. Older neighborhoods frequently have cast‑iron or clay pipes with scaling and root intrusion—conditions that determine whether a full structural lining or a targeted epoxy restoration is the better solution. Understanding these constraints helps contractors plan the inspection, cleaning, and lining approach that yields the best outcome.

From those constraints it’s clear how a provider like Pipeliners adapts materials and workflows to Arizona’s soils and climate.

How Pipeliners Adapts to Arizona’s Soils and Climate

We tailor trenchless workflows for Arizona by prioritizing thorough pre‑inspection, selecting resin systems that perform in local temperatures, and choosing curing methods that fit site access. In caliche areas we emphasize detailed camera mapping and aggressive hydro jetting to remove mineralized scale and roots so liners seat and bond properly. Resin selection and cure schedules are adjusted to ensure full polymerization in higher ambient temperatures. For water‑line corrosion or pinhole leaks we work with licensed ePIPE partners and account for warranty limits when recommending solutions. These adjustments reduce the risk of adhesion problems or voids and improve long‑term performance in Arizona’s environment.

Adapting methods to local geology lowers the chance of post‑repair issues and leads naturally to the next homeowner concern: cost.

How Much Does Trenchless Sewer Repair Cost in Arizona?

Trenchless sewer repair costs in Arizona depend on pipe length, diameter, material, damage severity, access needs, and site conditions. A transparent estimate includes a camera inspection, cleaning/prep (usually hydro jetting), materials and labor for CIPP lining or ePIPE coating, plus any point repairs or access work. The table below summarizes common cost components and representative ranges so homeowners and managers can get a rough sense of likely expenses.

The table below outlines principal cost drivers and representative examples for trenchless repairs in Arizona.

| Repair Component | Cost Factor | Typical Range / Example |

|---|---|---|

| Camera Inspection | Visibility and length of run | $200–$600 typical depending on scope |

| Cleaning/Prep (Hydro jetting) | Scale, roots, debris | $300–$1,000 depending on severity |

| CIPP Drain Lining | Pipe diameter/length | $80–$250 per linear foot typical range |

| ePIPE Water-line Restoration | Interior corrosion & length | Project-based; multiples of linear foot costs |

| Access & Site Complexity | Urban access, permits, caliche | Varies; can add several hundred to thousands |

Breaking costs down this way helps you compare itemized quotes from different providers and avoid surprises in final pricing.

Key cost drivers to keep in mind for Arizona projects:

- Pipe length and diameter: More footage and larger pipe sizes increase materials and labor.

- Severity of damage: Major structural issues or collapsed sections need extra prep or spot repairs.

- Pipe material: Cast iron and heavily scaled pipes usually require more extensive cleaning.

- Access and site conditions: Caliche, paved surfaces, and tight access raise mobilization complexity and cost.

- Warranties and certifications: Specialty systems like ePIPE or warranty‑backed installs can carry a premium.

These factors lead into Phoenix‑specific considerations and underline the value of scheduling a camera inspection to get an itemized scope; Pipeliners USA provides service‑area assessments and written warranty details to help you compare options.

What Drives Pipe Relining Costs in Phoenix, AZ?

In Phoenix, relining costs are influenced by urban access, the pipe’s internal condition, and savings from avoided surface restoration. Tight lots, driveways, and limited parking can require segmented work or shifted labor schedules that affect cost. Internal issues—scale, root intrusion, and joint separation—dictate cleaning and spot repairs before lining. Diameter and total linear footage determine material quantities and curing time. For example, a 50‑foot residential lateral relined with CIPP can be estimated after inspection and cleaning; avoiding driveway or hardscape replacement can represent significant savings over open‑trench work.

A thorough inspection and a clear scope are essential to produce an accurate estimate and prevent surprises during the project.

How Trenchless Repair Lowers Total Project Cost

Trenchless repair saves money mainly by avoiding costly surface restoration, shortening labor time, and reducing indirect disruption costs. When excavation would require removing driveways, patios, mature landscaping, or digging through heavy caliche, restoration costs often exceed excavation itself—no‑dig methods prevent most of that expense. Faster completion also reduces labor hours and downtime for households or businesses. Combined with the extended service life of modern liners and epoxy coatings, trenchless rehabilitation frequently proves more cost‑effective than full replacement over the pipe’s life cycle.

Typical saving categories:

- Avoided landscaping and hardscape restoration

- Shorter labor and equipment rental periods

- Reduced downtime and indirect disruption costs

Together these benefits make trenchless rehab a compelling alternative in many situations.

What Trenchless Services Do We Offer in Arizona?

Our Arizona trenchless offerings include drain and sewer lining, epoxy water‑line restoration, pipeline cleaning, and camera inspection—services for both residential and commercial properties. Typical work includes CIPP drain lining, ePIPE potable water restoration, hydro jetting for cleaning and prep, and pipe camera inspection for diagnostics and QA. The list below summarizes these core services and common use cases.

Core trenchless services available in Arizona:

- Trenchless Drain Pipe Lining (CIPP): Structural rehabilitation of sewer laterals and mains without excavation.

- ePIPE Water Line Restoration: Epoxy lining for potable water pipes to seal pinhole leaks and slow corrosion.

- Hydro Jetting Services: High‑pressure cleaning to remove roots, scale, and debris before lining.

- Pipe Camera Inspection: Diagnostic evaluations and post‑repair verification to document condition and results.

| Service | Primary Use Case | Warranty / Turnaround | Area Served |

|---|---|---|---|

| CIPP Drain Lining | Structural sewer rehabilitation | Long‑term lining warranties common; 1–2 day typical turnaround for short runs | Metro and suburban Arizona |

| ePIPE Restoration | Interior water‑line corrosion and pinhole leaks | Company‑provided warranty examples exist; project‑based timelines | Residential & commercial water systems |

| Hydro Jetting | Cleaning and scale/root removal | Prep step; usually same‑day or next‑day scheduling | Statewide support for lining projects |

| Camera Inspection | Diagnostics and post‑repair verification | Inspection report provided; scheduling flexible | All service areas |

How ePIPE Water‑Line Restoration Works and Where We Use It

ePIPE restores potable water lines by applying an internal epoxy coating that seals pinhole leaks and slows corrosion. The process begins with a camera inspection to locate affected runs, followed by cleaning or mechanical prep to remove loose scale. An epoxy system is then applied and cured to create a seamless interior coating that reduces leaks and extends service life. Pipeliners USA offers ePIPE through trained, licensed partners and notes warranty coverage for qualifying installations. ePIPE is a practical alternative to full replacement when lines have pinhole leaks or uniform corrosion rather than catastrophic failure.

Knowing when ePIPE is appropriate helps owners choose between targeted restoration and full replacement; the next section explains why hydro jetting is essential prep for both CIPP and epoxy methods.

Why Hydro Jetting Matters for Trenchless Prep

Hydro jetting uses high‑pressure water to remove roots, scale, grease, and debris from inside pipes so linings and coatings can adhere properly and cameras can capture accurate diagnostics. Pressure and nozzle selection vary by pipe material and obstruction type, but the goal is the same: clean the full circumference and length of the pipe to prevent voids and delamination. Hydro jetting is usually preferred over mechanical snaking when scaling or root growth is extensive because it cleans more completely and reduces the risk of trapped debris after lining. If a section has collapsed, a hybrid approach with spot excavation or mechanical removal may be required, which then determines whether rehab or replacement is the right path.

Why Choose Pipeliners for Trenchless Repairs in Arizona?

Pipeliners USA focuses on no‑dig, warranty‑backed rehabilitation solutions for Arizona properties, highlighting fast turnaround, licensed partner networks for specialty systems, and long‑life protection claims for epoxy and lining systems. Company claims across service materials include permanent repairs without demolition, epoxy pipelining protecting pipes for decades, and many jobs completed in one to two days. We present these claims so homeowners can compare providers when evaluating local trenchless options.

| Service | Claim / Feature | Supporting Detail |

|---|---|---|

| Drain Lining (CIPP) | 20‑year warranty | Company‑provided warranty duration cited for drain lining |

| ePIPE Water Restoration | 10‑year warranty | Company‑provided warranty duration cited for ePIPE |

| Epoxy Pipelining | 50+ year protection claim | Company‑claimed lifespan based on epoxy lining durability |

| Turnaround | 1–2 day typical | Company‑provided typical project duration for many jobs |

What Warranties and Guarantees Support Our Work?

Pipeliners USA lists specific warranty lengths for major trenchless products—for example, a 20‑year warranty for drain lining and a 10‑year warranty for ePIPE installations. Those timeframes give homeowners a baseline expectation, but warranty details—transferability, exclusions, and maintenance requirements—should be reviewed in the written document that accompanies any estimate. Ask for clear, written warranty terms and post‑repair inspection criteria so the coverage matches your expectations.

Understanding warranty durations is useful when comparing long‑term value between lining and replacement, and it ties into what customers typically report about outcomes and service quality.

What Customers Say About Trenchless Work in Arizona

Customer feedback commonly highlights minimal disruption, efficient crews, and durable results after trenchless repairs—especially when providers deliver thorough inspection, cleaning, and documentation. While we don’t reproduce individual quotes here, common themes are quick turnaround and the benefit of avoiding landscape and hardscape replacement. We recommend asking providers for recent, local references and before‑and‑after camera footage so you can validate performance in soils and access conditions similar to your property.

These testimonial themes point to three important vetting steps: verify written warranty terms, request before‑and‑after camera reports, and confirm licensed partners for systems like ePIPE.

Which Pipe Problems Can Trenchless Technology Fix in Arizona?

Trenchless methods address many common issues: root intrusion, cast‑iron scaling and corrosion, pinhole leaks in water lines, and large holes that haven’t caused full collapse. Typical approaches include hydro jetting and lining for roots and scale, epoxy coatings for internal water‑line corrosion, and full‑span CIPP structural lining for major defects when the host pipe still retains basic integrity. The list below pairs common problems with likely trenchless solutions so you can judge whether repair or replacement is probable.

- Root intrusion: Remove roots with hydro jetting and seal joints with CIPP lining to prevent recurrence.

- Cast iron scaling: Remove scale and install a structural lining to restore flow and strength.

- Pinhole leaks/corrosion: Apply epoxy restoration (ePIPE) to coat interiors and stop leaks without digging.

- Large holes: Assess structural viability; CIPP can seal large holes if the host pipe still holds alignment, otherwise replacement may be necessary.

These pairings help homeowners match visible symptoms to likely repair paths and set expectations for inspection and next steps.

How Trenchless Repair Handles Roots and Cast‑Iron Scaling

For roots and cast‑iron scaling, the standard approach is thorough cleaning with hydro jetting or mechanical cutters, followed by installing a liner that creates a smooth, continuous interior barrier. Hydro jetting removes biological material and mineral buildup that would prevent the liner from seating properly; once cleaned, a CIPP liner seals joints and smooths the interior to reduce future root intrusion and improve hydraulic performance. Scaling that narrows the pipe is removed and then covered by the liner to restore effective diameter.

This preserves the host pipe’s outer envelope while reducing recurrence, and it leads naturally to how we handle more severe defects.

Solutions for Large Holes and Severe Corrosion

Large holes and severe corrosion require a diagnostic decision. If the host pipe retains enough structural continuity, full‑span CIPP lining can bridge and seal defects while restoring longitudinal strength. If the pipe is fractured or collapsed beyond rehabilitation, replacement is the safer long‑term choice. Epoxy ePIPE coatings are effective where wall thickness remains serviceable but interior corrosion or pinhole leaks are present. Clear decision criteria—camera inspection, deflection measurements, and structural assessment—guide whether rehab or replacement is the right strategy.

Early inspection helps avoid incomplete repairs and ensures the selected method aligns with long‑term preservation goals.

Frequently Asked Questions

What lifespan can I expect from a trenchless repair?

Lifespan varies by method and materials. CIPP linings are commonly expected to last many decades—industry estimates often range from several decades up to 50+ years depending on the system and conditions—while epoxy coatings used in ePIPE projects typically offer long service life as well, though manufacturer‑specific expectations vary. Environmental conditions, pipe material, and maintenance all influence longevity, so plan for periodic inspections to confirm performance.

Are trenchless repairs suitable for every pipe type?

Trenchless methods work on many pipe materials, including clay, cast iron, and PVC, but suitability depends on condition. Pipes that are completely collapsed or fragmented may require replacement. A thorough camera inspection is the practical first step to determine whether trenchless rehab is appropriate for your situation.

How can I tell if my pipes need trenchless repair?

Common signs include frequent backups, slow drains, visible leaks, strange odors, wet spots in the yard, or gurgling drains. These symptoms justify a camera inspection, which gives a clear view of the pipe condition and helps identify the right repair approach.

What prep do I need to do before a trenchless repair?

We start with a camera inspection and then clean the pipe interior—often with hydro jetting—to remove roots, scale, and debris. Homeowners can help by clearing access points and ensuring the work area is accessible for the crew and equipment. Proper prep is essential so the lining or coating adheres correctly and the repair performs as expected.

Can trenchless repairs be done in winter or extreme weather?

Yes, but weather can affect curing and scheduling. Cold temperatures may require modified curing methods or materials, and extreme heat can also influence work windows. Experienced providers adjust procedures and materials to accommodate seasonal conditions and maintain repair quality.

What should I expect during the trenchless repair process?

Expect minimal surface disruption. The typical sequence is camera inspection, cleaning, lining or epoxy application, curing, and a final camera inspection to document results. Many residential jobs finish in a day or two, though scope, access, and site conditions can extend that timeline.

Conclusion

Trenchless pipe repair gives Arizona homeowners a way to fix common underground problems with less mess, shorter timelines, and long‑lasting results. Techniques like CIPP and ePIPE address roots, scaling, corrosion, and leaks while preserving landscaping and hardscape. If you’re weighing repair versus replacement, start with a camera inspection to get a clear scope and written estimate—including warranty terms—so you can compare options. Contact us to schedule an assessment and learn how our trenchless solutions can protect your property’s plumbing with minimal disruption.