How Plumbers Use Cured-in-Place Pipe Lining to Avoid Digging and Demolition

How Plumbers Use Cured-In-Place Pipe Lining to Avoid Digging and Demolition: The Ultimate No-Dig Sewer Repair Guide

Cured-in-place pipe (CIPP) lining is a trenchless rehabilitation technique that creates a structurally sound pipe-within-a-pipe by inserting a resin-saturated liner into a damaged conduit and curing it in place. This article explains how CIPP works, why plumbers increasingly choose it to avoid large excavations, the installation workflow, comparisons with other trenchless methods, expected lifespan and maintenance, potential risks, and cost drivers property owners should expect. Readers will learn the concrete steps plumbers take—from sewer camera inspection through cleaning, liner insertion, curing, and final inspection—and practical decision criteria for when CIPP is the right no-dig solution. The guide uses current research perspectives (as of June 2024), technical distinctions (UV vs hot-water curing, felt vs fiberglass liners), and actionable tables and lists to aid homeowners, property managers, and plumbing professionals in planning trenchless sewer repairs. First we define CIPP and outline the core installation process so you can quickly evaluate whether a no-dig relining approach suits your pipes.

What Is Cured-In-Place Pipe Lining and How Does It Work?

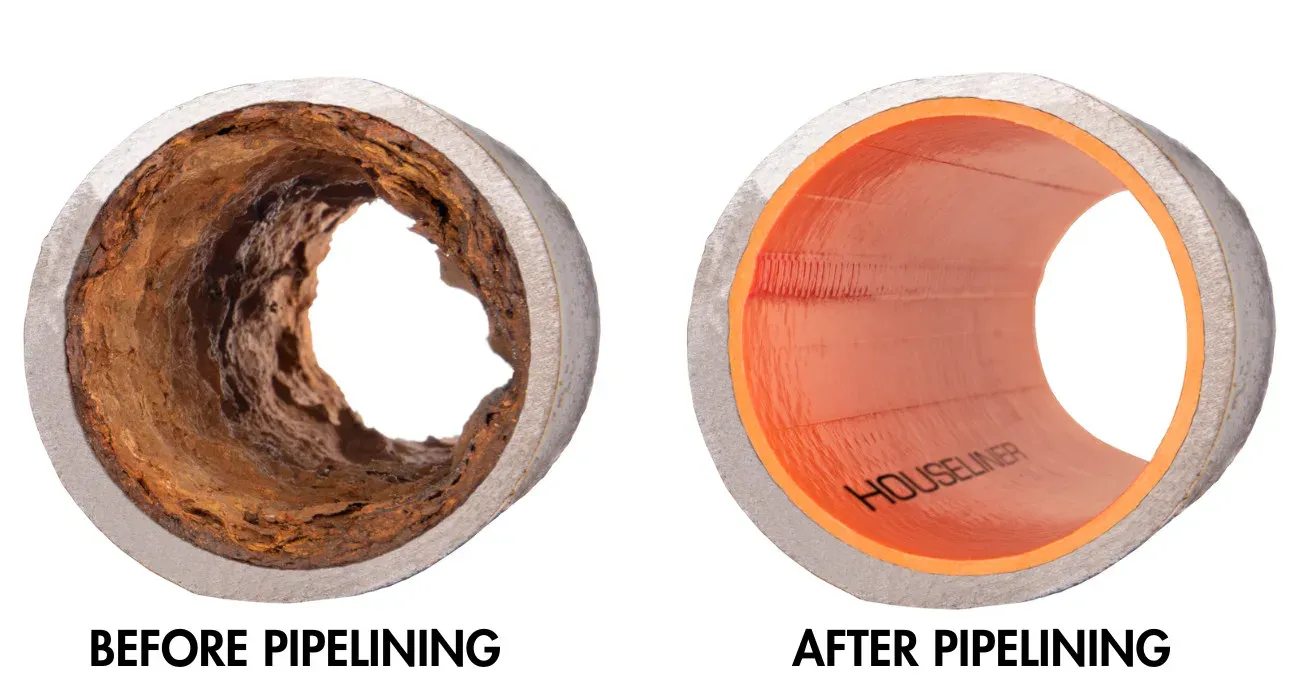

Cured-in-place pipe lining is a trenchless pipe rehabilitation method that rehabilitates an existing sewer line by inserting a flexible, resin-impregnated liner into the host pipe and curing it so the liner bonds to the inner wall, creating a new seamless conduit. The mechanism relies on three core components: a carrier liner (felt or fiberglass), a thermosetting resin (epoxy, polyester, or vinyl ester), and a curing system (UV light, hot water/steam, or ambient cure). This approach restores structural integrity, resists corrosion and root intrusion, and reduces surface disruption because the work is performed through small access points rather than full trenching. Understanding the materials and curing choices clarifies why CIPP is widely used for run-through repairs where digging would be costly or destructive. Grasping the broad mechanism leads directly to the specific definition and role CIPP plays within the wider trenchless technology family.

What Is CIPP Lining and Its Role in Trenchless Pipe Repair?

CIPP lining, commonly called CIPP or pipe relining, functions as a rehabilitative “pipe within a pipe” that preserves alignment while restoring strength and hydraulic performance. The liner material is typically a felt or fiberglass tube that is saturated with epoxy or other thermosetting resin before insertion; once cured, this composite forms a continuous new pipe. CIPP is a subset of trenchless technology used when existing pipelines are structurally compromised by corrosion, cracks, or infiltration but remain largely continuous and accessible via access points. Because it avoids open trenches, CIPP reduces the need for surface restoration and is especially valuable under driveways, sidewalks, and landscaped areas where excavation would be disruptive. Knowing this role helps set expectations for when relining is feasible and when replacement may still be necessary.

Further research highlights the specific properties and advantages of UV-cured CIPP, particularly when utilizing fiberglass liners.

UV Cured CIPP: Properties, Structure & Fiberglass Liners

One of the methods of curing (Cured-In-Place Pipe) CIPP pipes is the curing using ultraviolet (UV) light. The main difference from common CIPP types is in the structure of the liner material. In terms of material, it is a woven fiber glass fabric which is saturated with vinyl ester or polyester resin. In general, these pipes are more resistant to chemicals and achieve higher values of flexural properties. The paper focuses on the investigation of the short-term mechanical properties using three-point bending test and structure of UV cured CIPP liners. The computed tomography (CT) was used for the analysis of CIPP internal structure and composition.

Properties and Structure of UV Light Cured CIPP Composites, 2021

How Do Plumbers Perform the CIPP Installation Process Step-by-Step?

Below is the typical sequence plumbers follow when installing CIPP lining; each step is focused on restoring pipe function without excavation and often completes residential projects within one to three days depending on run length.

- Camera inspection and mapping to locate defects and measure run length.

- Pipe cleaning using hydro-jetting and mechanical tools to remove debris and roots.

- Liner preparation: saturating the felt or fiberglass tube with the chosen resin.

- Liner insertion via inversion or pull-in-place using winches or air pressure.

- Curing with the selected method (UV light, hot water/steam, or ambient cure).

- Final camera inspection to verify bond, alignment, and absence of leaks.

- Reinstatement of lateral connections and minor surface restoration if needed.

This numbered workflow is the practical foundation for assessing project time, equipment needs (sewer camera, hydro-jetter, curing system), and when to consult a licensed plumber for a site-specific plan.

What Are the Key Benefits of Using CIPP Lining for No-Dig Sewer Repair?

CIPP lining delivers multiple high-impact advantages for property owners: it minimizes surface disruption, shortens project timelines, improves pipe hydraulics, and offers long-term durability that reduces lifecycle costs. By forming a continuous, corrosion-resistant liner inside the host pipe, CIPP restores structural capacity and reduces infiltration without replacing the entire pipe. The technique also often eliminates the need to remove driveways, lawns, and sidewalks, which materially lowers restoration expenses and homeowner disruption. Below is a quick, scannable comparison of typical benefit impacts to help homeowners weigh outcomes.

| Benefit Category | Typical Impact | Example |

|---|---|---|

| Minimal Disruption | High | Small access pits vs trenches; no lawn removal |

| Project Time | Medium-High | Residential relines often complete in 1–3 days |

| Durability | High | Expected multi-decade service life under normal conditions |

| Hydraulic Improvement | Medium | Smooth liner reduces friction and blockages |

| Environmental Impact | Medium | Less soil disturbance and waste compared to replacement |

This table highlights the practical upsides that drive adoption: less disturbance and faster recovery translate directly into lower direct and indirect costs. The next section examines specifically how CIPP minimizes excavation and what savings to expect over time.

How Does CIPP Lining Minimize Disruption and Avoid Excavation?

CIPP eliminates most open-trench work by requiring only small access pits or using existing manholes and cleanouts to reach target runs, which preserves landscaping, paving, and structures above the pipe. The liner insertion and curing all occur within the pipe interior, so surface restoration is typically limited to minor patching around access points rather than full replacement of driveways or lawns. This results in measurable time savings—projects that would take weeks with excavation can often be completed in days with CIPP—reducing lost use of driveways and commercial downtime. Because restoration accounts for a significant portion of total replacement costs, avoiding excavation yields a strong cost advantage. Understanding these disruption-savings leads naturally into the durability and lifecycle cost benefits CIPP provides.

The broader adoption of no-dig trenchless technologies like CIPP is driven by their significant social and economic benefits, particularly in avoiding the disruption and costs associated with traditional excavation.

No-Dig Trenchless Technology: Social & Economic Benefits

Major cities in most of the developing countries are becoming increasingly crowded. Conventional open-trench methods are expensive and lead to traffic disruption. The domestic government is looking at alternative approaches to install and rehabilitate aging underground utilities. The purpose of this study is to investigate the level of awareness and utilization of no-dig (i.e., trenchless technology) methods, the potential of their future growth, and their impact on social costs in a developing country.

Investigating the use of no-dig technologies for underground utilities in developing countries, E Zaneldin, 2020

What Cost Savings and Durability Advantages Does CIPP Provide?

CIPP reduces many cost components associated with full replacement: labor for deep excavation, heavy restoration, traffic control, and longer project duration. The material and labor for relining scale primarily with run length and diameter rather than with the surface restoration budget, so projects under sensitive surfaces see the largest savings. Industry experience shows CIPP liners typically offer a service life in the 50–100 year range under normal conditions, with potential to extend toward longer lifespans when installation quality, soil conditions, and usage patterns are favorable. Over time, lower maintenance frequency and improved hydraulic performance can yield strong lifecycle ROI compared to repeated spot repairs or piecemeal replacements. These durability and cost themes provide a natural segue into how CIPP stacks up against other trenchless techniques like pipe bursting and slip lining.

How Does CIPP Lining Compare to Other Trenchless Pipe Repair Methods?

CIPP is one of several trenchless options; comparing mechanics, ideal use cases, and trade-offs clarifies when each method is preferable. In brief, CIPP rehabilitates the existing pipe by lining it internally, slip lining inserts a smaller preformed pipe into the existing host, and pipe bursting fractures and replaces the old pipe with a new one by pulling the new pipe through. The table below summarizes these differences for quick decision-making.

| Method | Ideal Use Case | Pros | Cons | Typical Diameter Impact |

|---|---|---|---|---|

| CIPP Lining | Long runs with internal deterioration, intact alignment | Minimal surface restoration, seamless liner, corrosion resistance | Some diameter reduction, not ideal for severely collapsed pipes | Minor (depends on nominal liner thickness) |

| Pipe Bursting | Severely damaged pipes needing full replacement | Replaces pipe fully, can increase diameter | Requires better access, can shift surrounding soil | Same or larger than original |

| Slip Lining | Simple, straight sections with moderate damage | Simpler materials, durable | Reduces diameter significantly, may require annular grout | Significant (smaller internal diameter) |

This comparison shows why plumbers often favor CIPP when the host pipe’s alignment is acceptable and complete replacement is unnecessary. The next H3 expands on the technical differences between CIPP, pipe bursting, and slip lining.

What Are the Differences Between CIPP, Pipe Bursting, and Slip Lining?

CIPP creates a new structural layer by bonding a cured resin liner to the host pipe’s interior, preserving alignment and avoiding soil displacement. Pipe bursting physically breaks the old pipe while simultaneously pulling a new pipe through, effectively replacing the conduit and sometimes upsizing the line but involving more ground movement. Slip lining feeds a smaller-diameter pipe into the existing barrel and typically grouts the annular space; it is mechanically simple but reduces flow capacity due to a smaller bore. Each method has distinct mechanical impacts on surrounding ground and utilities, so plumbers evaluate host-pipe condition, alignment, and nearby infrastructure before recommending a technique. Understanding these mechanics makes it easier to choose the right trenchless approach.

When Should Plumbers Choose CIPP Over Alternative No-Dig Techniques?

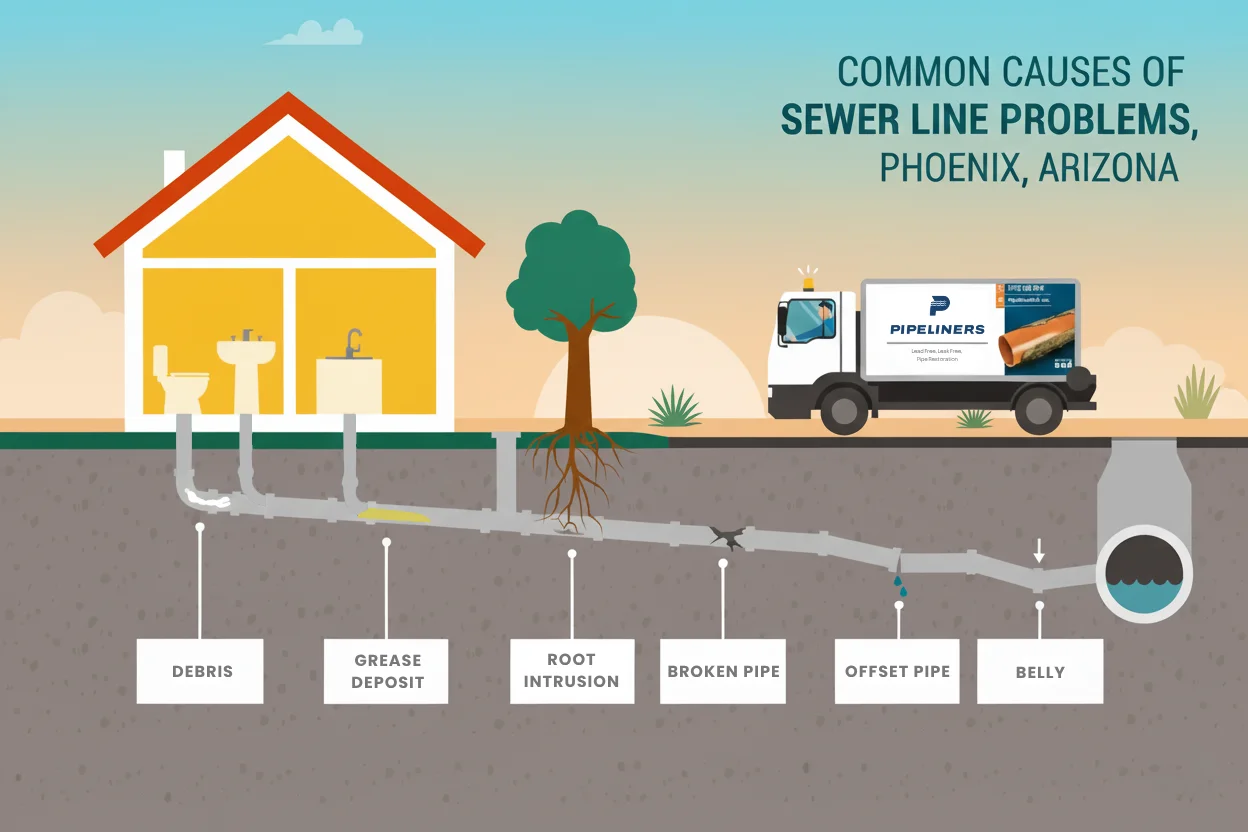

Plumbers typically select CIPP when internal deterioration (cracks, corrosion, infiltration) is the primary issue, the pipe remains largely continuous with acceptable alignment, and when surface restoration costs would be high. CIPP is less suitable when pipes are severely collapsed, misaligned beyond tolerance, or when diameter loss from relining would hinder hydraulic capacity. Practitioners often use a decision checklist that includes run length, pipe material (cast iron, clay, PVC, concrete), degree of offset, and proximity to sensitive structures. When full replacement is required due to collapse or misalignment, pipe bursting or open-cut replacement may be more appropriate despite higher surface disruption. These decision criteria lead into the expected lifespan and maintenance practices that preserve relined systems.

What Is the Expected Lifespan and Maintenance for CIPP Lined Pipes?

CIPP liners generally provide multi-decade service life when properly specified and installed; typical industry ranges note 50–100 years under normal residential or commercial use, with potential extension beyond that when resin selection, curing quality, and operational conditions are favorable. The liner’s longevity depends on resin chemistry, liner material, soil chemistry, temperature exposure, and workmanship during installation. Regular inspections and appropriate cleaning preserve the liner’s integrity and hydraulic performance, and routine checks help detect localized issues before they escalate. Below is a focused breakdown of lifespan expectations followed by maintenance practices to maximize service life.

However, it is crucial to acknowledge that the actual lifespan of CIPP liners is heavily dependent on the quality of installation, with improperly installed liners unlikely to achieve their projected longevity.

CIPP Liner Lifespan & Installation Impact

Nevertheless, improperly installed liners are unlikely to meet the expected 50-year lifespan. The lack of robust studies on liner lifespans and survival curves

Investigation of the Technical Service Life of Cured-In-Place Sewer Pipe Liners, N Caradot, 2024

| Lifespan Factor | Description | Typical Effect on Longevity |

|---|---|---|

| Resin Type | Epoxy vs polyester/vinyl ester | High: Epoxy often yields better chemical resistance |

| Curing Method | UV vs hot water/steam | Medium: UV can accelerate cure with less thermal stress |

| Installation Quality | Surface prep and adhesion | High: Proper cleaning and cure are essential |

| Operational Stress | Abrasion, chemicals, flow rates | Medium-High: Harsh conditions reduce service life |

This table clarifies how material choices and installation quality strongly influence expected lifespan and helps owners prioritize inspection and maintenance actions.

How Long Does CIPP Lining Last in Residential and Commercial Applications?

For most residential applications, CIPP liners offer an expected lifespan of around 50–100 years when installed correctly and used under typical domestic loading and flow conditions. Commercial or industrial settings may see wider variability because higher flows, chemical exposure, or heavier mechanical stresses can accelerate wear; in some well-controlled commercial installations, liners can exceed 100 years when corrosive exposures are minimal. Installation quality—particularly cleaning, proper resin saturation, and complete curing—remains the primary determinant of real-world performance. Recognizing these lifespan ranges informs inspection frequency and maintenance budgeting for property owners.

What Maintenance Practices Maximize CIPP Durability and Performance?

Preserving a relined sewer requires periodic inspection and conservative cleaning practices that avoid abrasive techniques that could damage the liner. Recommended actions include scheduled camera inspections every 2–5 years depending on risk profile, targeted hydro-jetting at moderate pressures to remove buildups, and root management strategies for nearby vegetation. Property owners should avoid repeated use of harsh chemicals that can attack some resin types and should document any unusual flows or odors for early contractor evaluation. Following a disciplined inspection and maintenance cadence helps detect early defects, enabling inexpensive repairs and extending the liner’s service life.

What Are the Potential Disadvantages and Safety Considerations of CIPP Lining?

While CIPP offers strong advantages, it also has limitations and safety considerations that must be managed: curing emissions and VOCs during installation, potential diameter reduction that may affect hydraulic capacity, and unsuitability for severely collapsed or misaligned pipes. Worker and homeowner safety protocols—including containment of curing off-gases, ventilation, and use of certified resins—mitigate environmental and health risks. Plumbers evaluate pipe condition and access to determine feasibility and may recommend alternative techniques when structural conditions exceed CIPP’s practical limits. Understanding these disadvantages helps set realistic expectations before choosing a no-dig repair.

Are There Health Risks Or Environmental Concerns During CIPP Installation?

Some CIPP systems can emit volatile organic compounds (VOCs) during curing, particularly with certain styrene-based resins; such emissions pose inhalation risks if not properly contained. Mitigation protocols include localized ventilation, temporary evacuation of indoor spaces when lateral connections are opened during cure, use of low-emission resins where possible, and personal protective equipment for workers. Licensed trenchless service providers follow safety guidelines to limit homeowner exposure and environmental release, and they document containment measures on-site. Awareness of these risks underscores the importance of hiring qualified contractors who adhere to safety standards and can explain mitigation steps before work begins.

What Limitations Does CIPP Have Regarding Pipe Condition and Diameter?

CIPP cannot reliably reconstruct a pipe that is excessively collapsed, grossly misaligned, or broken into multiple segments with large open voids; in such cases, structural replacement or pipe bursting is often necessary. Additionally, the liner’s wall thickness reduces the internal diameter slightly, which may be a limiting factor in small-diameter pipelines or systems already operating near capacity. Plumbers assess the host pipe using camera inspection and measurements to determine if the post-lining hydraulic capacity remains acceptable. If diameter loss or structural instability would impair performance, alternative trenchless or open-cut methods are recommended.

How Do Cost Factors Influence CIPP Lining Pricing and Project Planning?

Cost for CIPP projects depends on multiple variables that contractors evaluate when preparing an estimate: run length and diameter, access complexity, resin and liner material choice, curing method, reinstatement of laterals, and site-specific mobilization needs. Accurate project planning requires inspection data—camera footage, access maps, and knowledge of surface restoration needs—because those inputs directly affect labor and material quantities. Below is an actionable cost-driver matrix to help property owners understand how individual factors typically influence price and what information to gather before requesting quotes.

| Cost Factor | Description | Typical Effect on Price |

|---|---|---|

| Run Length & Diameter | Material volume and labor time | High |

| Access Complexity | Number and size of entry points needed | High |

| Liner Material & Resin | Felt vs fiberglass; epoxy vs polyester | Medium-High |

| Curing Method | UV equipment vs hot water/steam | Medium |

| Lateral Reinstatement | Reopening and sealing service connections | Medium-High |

This table shows the relative weight of each factor; preparing accurate inspection data significantly improves estimate precision and reduces the likelihood of change orders.

What Variables Affect the Cost of CIPP Pipe Repair Services?

Key variables that drive cost include the pipe’s length and diameter (directly affecting material and labor), the number and accessibility of entry points (which increase mobilization and labor), the chosen liner material and resin chemistry (higher-performance resins cost more), and the curing method (UV systems require specialized equipment). Other considerations include reinstating lateral connections, traffic control or permitting in public ways, and site-specific logistics that affect crew time. When plumbers produce quotes, they evaluate camera inspection footage, measure run segments, and note any restoration requirements to produce line-item estimates. Understanding these variables helps owners compare bids on an apples-to-apples basis.

How Can Property Owners Get Accurate Estimates for No-Dig Sewer Repair?

Property owners should supply detailed documentation—recent sewer camera inspection reports, clear access maps, and photos of surface conditions—and ask providers to itemize costs for materials, curing method, lateral reconnections, and restoration. Use a checklist when collecting quotes: request line-item pricing, ask which resin and liner type will be used, confirm warranty terms for materials and workmanship, and verify insurance and relevant licenses for the contractor. Ask about anticipated disruptions, curing-time windows, and cleanup responsibilities so you can compare total project impact rather than just headline price. Preparing this documentation and question set enables providers to generate accurate, comparable proposals.

For next steps, schedule a camera inspection with a licensed plumber or trenchless service provider to gather the objective footage and measurements contractors need to prepare precise estimates. A professional inspection is the most reliable path from evaluation to an accurate fixed-price proposal and will clarify whether CIPP is the appropriate no-dig solution for your situation.